Telecentric lighting in machine vision applications

Achieving precise and repeatable image quality is essential for machine vision applications like measurement, quality control, and inspection. To improve imaging precision, telecentric lenses and telecentric lighting are essential. We will first provide a brief overview of telecentric lenses in this article before delving into the benefits and drawbacks of telecentric lighting. In some cases, we will also look at the parallel backlight as an additional lighting option.

Please get in touch with us if you require any assistance or if you have any questions about our telecentric lenses and lighting.

Our website only features a small portion of our entire selection of telecentric lenses and lighting.

Please get in touch with us if you require any assistance or if you have any questions about our telecentric lenses and lighting.

Telecentric lenses for machine vision

Telecentric lenses are optical tools made to reduce perspective errors and offer uniform perspective and magnification over the whole imaging field. The optical components of telecentric lenses are arranged in a unique way, which sets them apart from conventional lenses. We offer a big portfolio of telecentric lenses. All telecentric lenses and pricing can be found by clicking on this link.

Rays entering telecentric lenses are intended to be parallel to the image sensor, producing rays that are almost perpendicular to it. This characteristic reduces perspective errors and distortions, enabling precise and reliable measurements. Telecentric lenses are therefore perfect for accurate feature extraction and precise dimensional measurements. Telecentric lenses also have minimal distortion and continuous magnification.

How works telecentric lighting in machine vision?

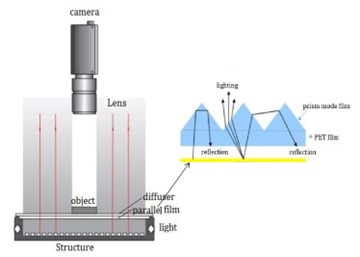

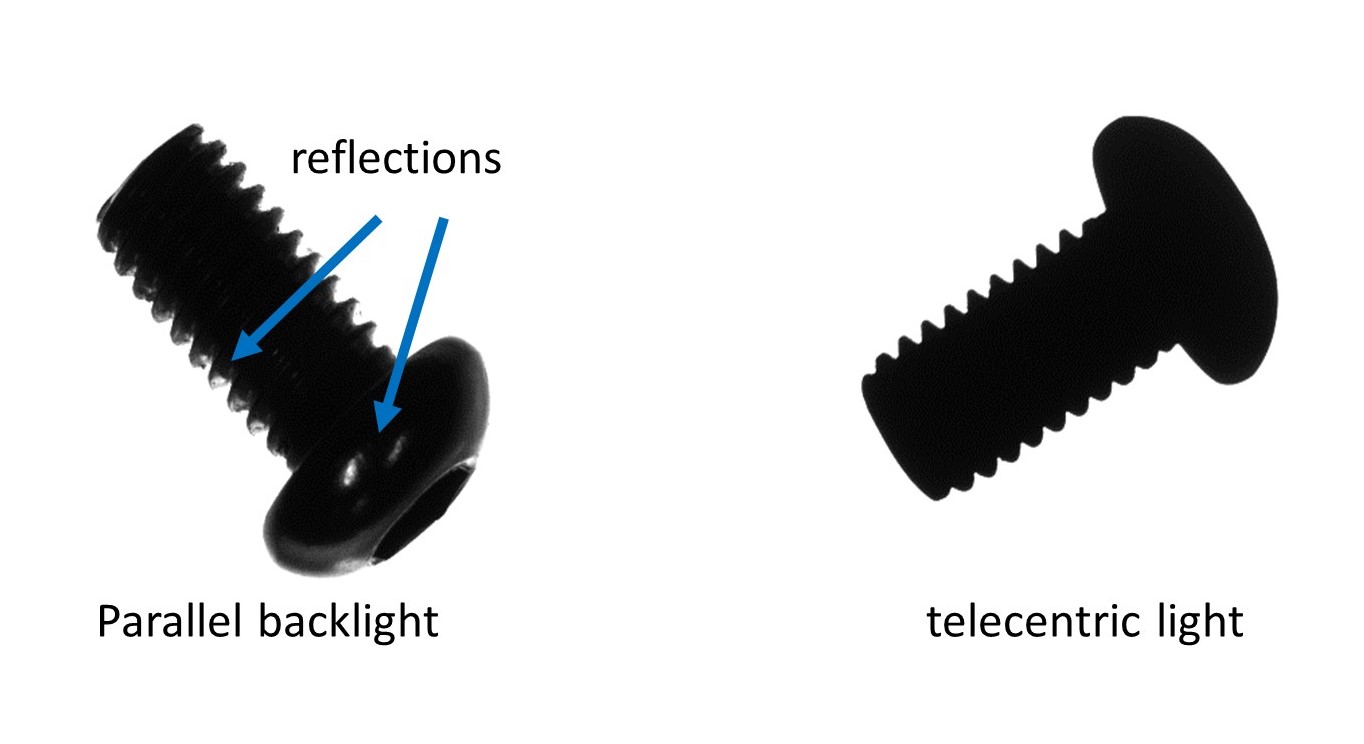

Working in tandem with telecentric lenses, telecentric lighting is a crucial component of the telecentric imaging system. Telecentric lights guarantee that the light rays are parallel and have a constant intensity throughout the whole field of vision, in contrast to traditional back illumination techniques that produce diffuse or undirected light rays. With the help of this parallel light beam arrangement, perspective errors and distortion are reduced, silhouettes are produced, and measurements are precise and image quality is constant.

Light rays are directed through a series of optical components to produce parallel light rays and a constant beam brightness in order to create telecentric lighting. This light beam is sometimes referred to as a collimated light beam.

You could think of the telecentric light as a telecentric lens that has been reversed.

Benefits of adding telecentric lighting

1. Diminished Reflections and Shadows

Telecentric lighting reduces unwanted reflections and shadows, which can have an impact on measurement accuracy and image quality. There is less chance of shadows from the object or the imaging system when there are parallel light rays.

2. Improved Accuracy of Measurements

In addition to telecentric lenses, a telecentric light also contributes to increased measurement accuracy by mitigating errors resulting from changes in illumination, perspective distortions, and effects related to depth.

3. Extended Operating Range

It permits longer working distances between the light source and the object. This adaptability comes in handy in situations where moving or adjusting the product requires clearance between the telecentric light and lens. For example, the space required for the robot arm to move.

4. Shorter exposure periods

Only the necessary area will illuminate by the collimated light. Consequently, the light source's entire power is utilized. High contrast and perfect illumination are made possible by this. Consequently, the machine vision camera's short exposure times lead to shorter machine cycle times.

Drawbacks of adding telecentric lighting

1. Cost of Equipment

Because telecentric lighting requires precise optics and specialized design, it can be more expensive than conventional lighting setups. For some applications, the expense of telecentric lenses and specialized light sources may be prohibitive.

2. Space Necessities

In a machine vision setup, the physical dimensions of telecentric lenses and light sources may necessitate additional space. This could be problematic when integrating the lighting system with existing equipment or in applications where there is a lack of space.

3. The installation process

It's crucial to remember that precise alignment of the optical components is necessary when using telecentric lighting. This guarantees peak performance and delivers the required level of image quality.

Parallel back lights for your telecentric lens project

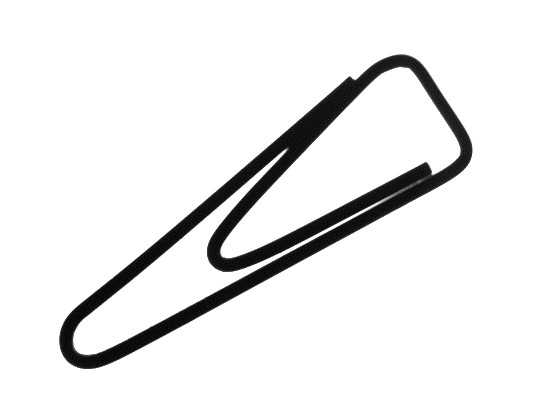

Telecentric lighting can be substituted with a Parallel Back Light in cases where cost or space constraints are important considerations. A specialized filter installed in parallel backlights lessens light emission from diffuse sources and produces more homogeneous, directed light.

Even though it might not offer the same degree of perspective control or depth perception, a parallel backlight has benefits in some situations:

- The Space-Saving Approach

Since parallel backlighting systems are frequently smaller than telecentric lighting arrangements, they are appropriate for applications with restricted space or when space optimization is a top priority.

- Equitable Lighting

The surface of the object can be evenly and uniformly illuminated with a parallel backlight. This guarantees constant quality of images.

- Contrast enhancement and edge detection

Parallel backlighting makes object contours and boundaries more visible, which enhances edge detection performance. Additionally, it boosts contrast, making it easier to distinguish between features, flaws, and irregularities in an object.

Conclusion

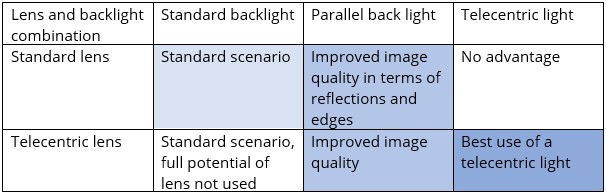

Telecentric lens and light systems provide significant benefits in terms of improved contrast and measurement accuracy. The advantages they offer are priceless, even though they might require more money and space. In scenarios where space constraints or financial concerns are paramount, a parallel backlight may offer a feasible and workable substitute. Improved edge detection capabilities and consistent illumination are provided by parallel backlighting. Machine vision system designers can choose the best option for their applications by carefully weighing the advantages and disadvantages of each lighting technique, guaranteeing accurate and dependable imaging results.