Menu

ZEBRA AURORA VISION IMAGE PROCESSING SOFTWARE

Zebra Aurora Vision (previously known as Adaptive Vision) is a market leader for image processing software for industrial automation. The following software packages are available:

- Zebra Aurora Vision Studio Professional -> design and run your own machine vision programs using an easy to use graphical user interface. 1 license for each development PC.

- Zebra Aurora Vision Studio Runtime -> A license to run programs developed with Zebra Aurora Vision Studio. With this license you can only execute programs, but not make changes in the program it selves.

- Zebra Aurora Vision Studio Library Add-on + code generator -> convert programs made in Zebra Aurora Vision Studio professional to C++ code, so it's easy to integrate in your own C++ program

- Zebra Aurora Vision Deeplearning Add-on -> license to use deeplearning tools with Zebra Aurora Vision Studio to quickly make robust vision programs of complex vision tasks. For every PC that runs or develops programs with deeplearning a license is required.

- Zebra Aurora Vision Library -> design and run your own machine vision programs using a comprehensive C++ and .NET library. 1 license for each development PC.

- Zebra Aurora Vision Library Runtime -> A license to run programs developed with Zebra Aurora Vision Library. With this license you can only execute programs, but not make changes in the program it selves.

Zebra Aurora Vision Software Success Stories

In terms of computer vision software, Zebra Technologies is at the forefront. With the help of the Aurora Vision software, users can easily create custom image processing algorithms for automation projects. Automation problems can be quickly and easily solved by users like computer vision integrators. Machine vision engineers are provided with a strong graphical environment and tools for industrial automation and quality inspection by Aurora Vision's image processing software.

The dataflow-based methodology used in Aurora Vision software includes a number of pre-built image analysis filters. Designed with experts in mind, it expedites the development of personalized projects and makes common application creation easier. Because of its versatility, computer vision engineers frequently use it to handle a variety of automation and quality inspection tasks in the industrial sector.

A variety of computer vision software packages for image processing are displayed on this Zebra Aurora software webpage, including:

- Aurora Vision Studio: A simplicity powerhouse, providing machine vision engineers with a graphical low-level programming environment for rapid development and simple customization.

- Aurora Vision Library: Offers C++ and.NET programmers ready-to-use features that allow them to create custom software for even the most intricate applications.

- Aurora Vision Deep Learning: With this software add-on, you can select which images as defective/labels, as well as train the program to work specifically for your needs. Use the Deep Learning OCR tool, which has been pre-trained, to delve deeply into optical character recognition. This is the ideal tool for interpreting damaged, hazy, or complex characters. It's the best way to get past visual obstacles in character recognition.

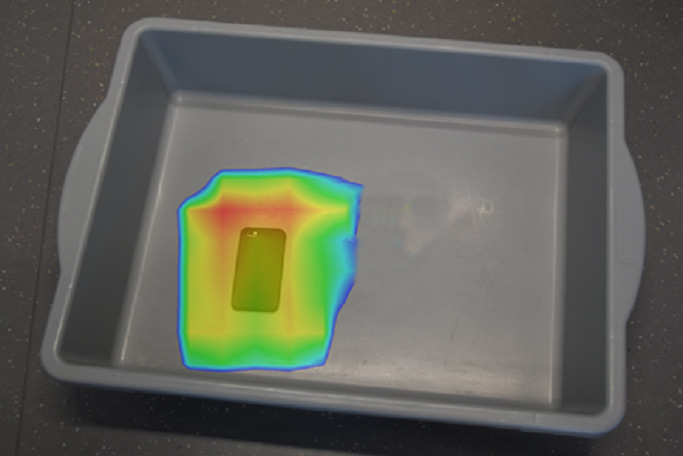

Airport trays verification

Zebra Technologies' Aurora Vision software comes with sophisticated deep learning add-on packages. There are sophisticated object detection algorithms available for verifying airport security trays. More precisely, as demonstrated by the groundbreaking work of Vienna University, the software enables users to design their own algorithms to suit their particular requirements. The university created an algorithm in Aurora Vision software for this example application, which allows it to identify and classify objects found in airport security trays.

Vienna University's algorithm demonstrates the flexibility of the software. It was painstakingly trained on a dataset of 150 images that included three distinct classes. There are three types of trays: one that is empty, one that has an object on it that was unintentionally left behind, and one that needs to be cleaned up because liquids have spilled on it. This customized strategy guarantees a thorough examination of tray contents, enhancing operational effectiveness and security protocols at airport checkpoints.

Test image - Object (with RelevanceHeatmap)

The effectiveness of this cutting-edge verification system depends critically on the use of machine vision cameras in conjunction with Zebra Aurora Vision. The real-time analysis of tray contents is made possible by the software's seamless integration with machine vision cameras. The system can recognize objects and produce informative heatmap visualizations by utilizing the combination of the machine vision camera and Aurora Vision's deep learning capabilities. The vision algorithm's heatmap functions as a visual reference. In terms of security procedures, Zebra Aurora Vision software and machine vision cameras elevate airport tray control to a new degree of accuracy and effectiveness. Click this link to read about the specifics of this success story.

Diameter Inspection

For This application, a few engineers worked on this vision project and created a cutting-edge application for tempered steel ring diameter dimension inspection using the Zebra Aurora Vision software. Examining steel rings for roundness and inner diameter measurements. Through the utilization of machine vision cameras, this sophisticated system offers extremely precise evaluation. As a result, the engineers can inspect these crucial parts with an amazing tolerance of up to +/- 0.1 mm.

This success story would not be possible without the Zebra Aurora Vision software, which offers a stable platform for diameter inspection that surpasses traditional boundaries. Real-time measurements and analysis are made easier by its adaptive algorithms, which are seamlessly integrated with machine vision cameras. The inner diameter of the steel rings is guaranteed to meet strict quality standards by the Aurora Vision software. This discovery not only represents a major development in industrial inspection procedures but also highlights the revolutionary effect of Aurora Vision software in obtaining unmatched precision and effectiveness in dimensional evaluations. Click this link to read about the specifics of this success story.

PCB Positioning

In the field of PCB positioning, Zebra Aurora Vision software—especially the sophisticated Zebra Aurora Vision Studio—is revolutionizing PCB positioning and advancing technology. In this application, a 5MP monochrome camera, like our MER2-503-36U3M camera, is used in conjunction with the Aurora Vision software. With the remarkable measurement accuracy of up to 0.05mm, this combination allowed for the precise determination of PCB positioning.

The inspection process is given a new dimension by the use of Aurora Vision software, which makes it possible to precisely examine PCB positioning. The software's adaptability is demonstrated by its ability to work with flexible macro filters, which enable customized adjustments to meet application-specific requirements. This success story is unique because of its seamless integration feature, which enables speedy DLL file export. This feature allows users to easily integrate the solution into their own operating software while also streamlining the integration process. Click this link to learn more about this success story.